Since 2025, Arichi has exported 20 sets of mobile cold storage facilities to countries such as Vietnam, Malaysia, and Thailand, which are used by local merchants for the cold storage of fresh produce, fruits, food, and medicines.

Customer feedback: "Compared with traditional cold storage facilities, Archi's mobile cold storage has saved 70% of the construction time for building cold storage facilities, and the electricity and construction costs have been significantly reduced."

Mobile cold storage

Mobile Cold Storage vs. Traditional Cold Storage: Core Advantage Comparison

- Construction period & Installation convenience

✅ Mobile cold storage: Mobile base frame structure, no foundation construction required, ready for use in 1 day

❌ Traditional cold storage: requires civil construction, steel structure construction, long construction period, greatly affected by weather

- Flexibility and scalability

✅ Mobile cold storage: Plug and play, reportable at any time (for temporary storage, seasonal needs)

❌ Conventional cold storage: Fixed structure, relocation cost is extremely high, expansion requires dismantling and reconstruction

- Cost-effectiveness

✅ Mobile cold storage: 30%-50% lower initial investment (no construction cost)

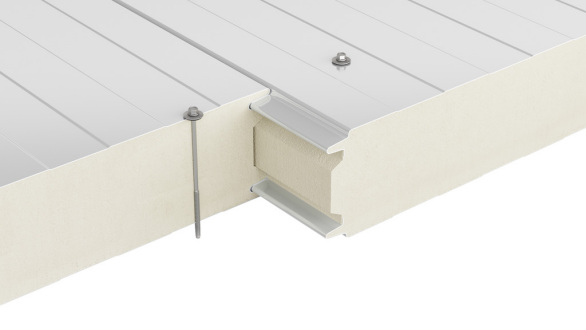

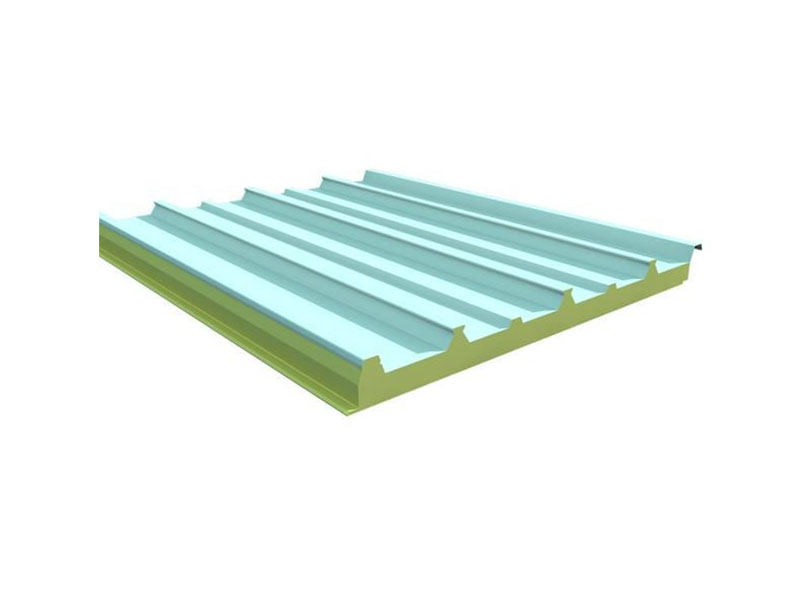

Energy-saving designs (such as polyurethane /PIR insulation) save over 40% of electricity

The rentable model lowers the threshold for small and medium-sized enterprises

❌ Traditional cold storage: high initial infrastructure and equipment investment, high energy consumption

Installation of mobile cold storage

Typical case

Thai durian exporters: By using mobile pre-cooling warehouses, the temperature drops within one hour after harvest, reducing the loss rate from 30% to 8%

Vietnam Vaccine Distribution Center: Temporary deployment of mobile cold storage, completion of GSP-certified warehouse construction within 48 hours

Mobile cold storage is becoming the preferred solution for upgrading the cold chain in Southeast Asia!