Mobile cold storage, with its advantages of convenience, energy efficiency and low cost, is gradually changing the landscape of the cold chain industr

With the rapid development of fresh food e-commerce, cold chain logistics and modern agriculture, the demand for cold storage from merchants is increasing day by day. Traditional fixed cold storage facilities have long construction periods, large investments and poor flexibility. In contrast, mobile cold storage facilities, with their modular design, rapid deployment and energy conservation and high efficiency, are becoming an innovative choice in the cold chain industry.

As a leading mobile cold storage manufacturer in China, we are committed to providing customers with more flexible, economical and intelligent cold chain storage solutions. This article will make a detailed comparison of the core advantages of mobile cold storage and traditional cold storage to help enterprises make better decisions.

Mobile cold storage vs. Traditional cold storage

Construction period: from several months to several days, it can be put into use quickly

Construction period: from several months to several days, it can be put into use quickly

Mobile cold storage: It adopts a modular design, leaving the factory as a finished product. After being transported to the site, it only requires simple debugging and can be used. It can be put into operation within 1-3 days at the fastest, meeting the urgent storage needs.

Traditional cold storage: It requires civil construction, equipment installation and commissioning, and the construction period is usually 1 to 2 months, which delays business opportunities.

Applicable scenarios: Temporary storage during the peak season for fresh produce, emergency cold chain demands, and storage of seasonal agricultural products.

- Investment cost: Reduce the initial investment by more than 50%

Mobile cold storage: No foundation construction is required, and there is no high civil construction cost. The overall investment is only 30%-50% of that of traditional cold storage, and it can be leased or purchased in installments, reducing financial pressure.

Traditional cold storage: It requires land approval, construction, and equipment installation, with a large initial investment that is difficult for small and medium-sized enterprises to bear.

- Flexible relocation: Move freely according to business needs

Mobile cold storage: It adopts container or trailer design, can be hoisted and transported as a whole, and can be easily relocated to a new site, adapting to business expansion or regional adjustment.

Traditional cold storage: Fixed buildings that cannot be moved. Relocation requires demolition and reconstruction, which incurs extremely high costs.

Typical applications:

Temporary storage of agricultural products at the origin → transportation to the wholesale market

The urban fresh food distribution center flexibly adjusts the storage locations

Emergency disaster relief cold chain material turnover

- Energy conservation and environmental protection: Efficient cooling, saving over 30% of electricity

Mobile cold storage

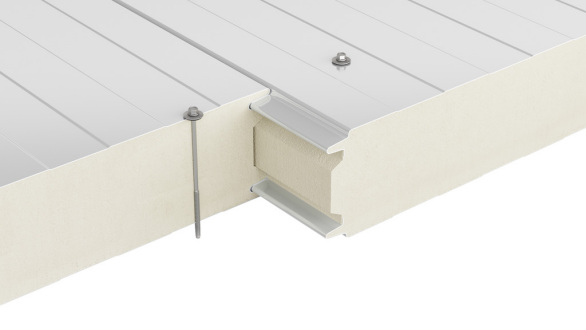

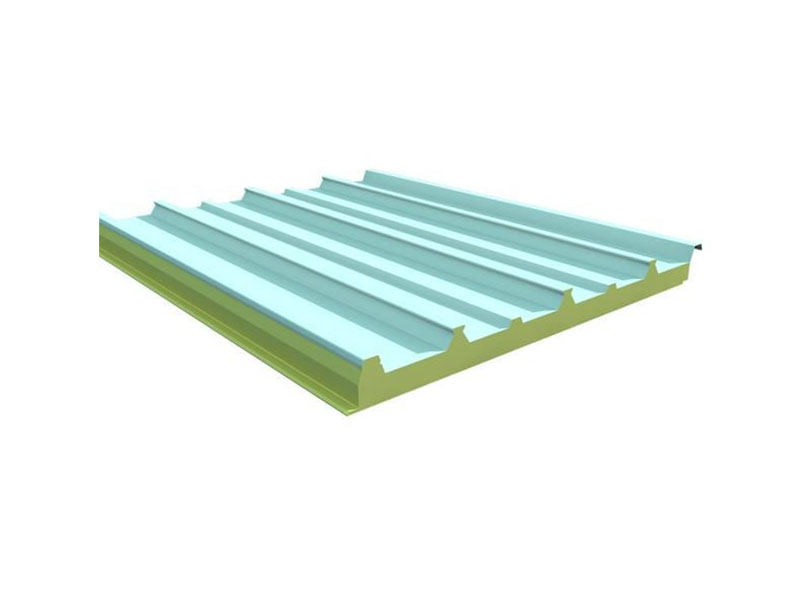

It adopts a polyurethane high-efficiency insulation layer with a thermal conductivity as low as 0.018W/(m·K), resulting in minimal cold loss.

Equipped with a variable frequency refrigeration unit, energy consumption can be adjusted as needed, saving 30% to 50% of electricity compared with traditional cold storage.

Optional solar power supply is available to achieve green and low-carbon operation.

Traditional cold storage

The insulation performance is greatly affected by the construction quality, and the cold energy is prone to loss.

Traditional fixed-frequency compressors consume a lot of electricity and have high long-term operating costs.

- Intelligent Management: Remote monitoring makes operation and maintenance more convenient

Mobile cold storage

View temperature, humidity and equipment status in real time.

Intelligent system, automatic notification of abnormal situations, reducing the loss of goods.

Low maintenance requirements, no need for professional computer room managers.

Traditional cold storage

Relying on manual inspection results in a slow response speed.

Equipment failure may lead to large-scale downtime and high maintenance costs.

Wide application scenarios: Full cold chain coverage from the field to the dining table设备故障可能导致大规模停机,维护成本高。

the full cold chain coverage, mobile cold storage, with its flexibility, can meet the needs of various industries/Agriculture: pre-cooling in the field, preservation of fruits and vegetables, temporary breeding of aquatic products; logistics: temporary transfer warehouse, urban distribution cold storage; retail community group purchase warehousing, supermarket backup cold storage; Emergency: vaccine storage, disaster relief material cold chain应用场景广泛:从田间到餐桌,全冷链覆盖,移动式冷库,以其灵活性,可满足各行业/农业的需求:田间预冷、果蔬保鲜、水产品临时养殖;物流:临时中转仓库、城市配送冷库;零售社区团购仓储、超市备用冷库;应急:疫苗储存、救灾物资冷链

The future belongs to a flexible and efficient cold chain model

Mobile cold storage, with its advantages of rapid deployment, low cost, energy conservation and intelligence, is reshaping the cold chain industry. Whether it is temporary storage for small and medium-sized enterprises or flexible replenishment for large logistics companies, mobile cold storage can provide more efficient and economical solutions.

As a leading manufacturer of mobile cold storage in the industry, we are committed to providing customers with customized and cost-effective cold chain products, helping enterprises reduce costs and increase efficiency, and seize market opportunities!作为行业领先的移动冷库制造商,我们致力于为客户提供定制化、高性价比的冷链产品,帮助企业降本增效,抢占市场先机!